Occasionally, we find ourselves influenced by the briefest of conversations. Such was a recent experience after speaking to Steve Parsons of Eyos Expeditions. Steve recently brought FPB 78 (Ugly Betty) through the North West Passage. Previously, he was the commissioning captain for FPBs launched at Circa Marine. Short of Circa Marine themselves, Steve probably knows more about FPB performance than all but one man alive. So, I was in for quite an education, and I'll report on just two aspects of that in this Blog.

FPB has a much-vaunted capability to surf in a following sea (see the Youtube video below of Cochise FPB 78). Waves slowly pick up the stern, pushing the hull forward as she slips down the wave. FPBs limit the bow digging as speed increases, preventing bow steer and a potentially dangerous broach. Watch the many videos available, and you can see how comfortable they seem to be in this condition. Steve Parsons described this situation in graphic detail. So far, so good.

Steve also talked about his experiences during FPB 70 and FPB 78 commissioning and sea trials. When a vessel designed for a hull speed of around 12 KN finds herself surfing over 20 KN plus, this is outwith the experience of most sailors or naval architects. The hydrodynamics become unusual, and the forces in play are quite large, giving rise to two issues as detailed below.

Rudder balance

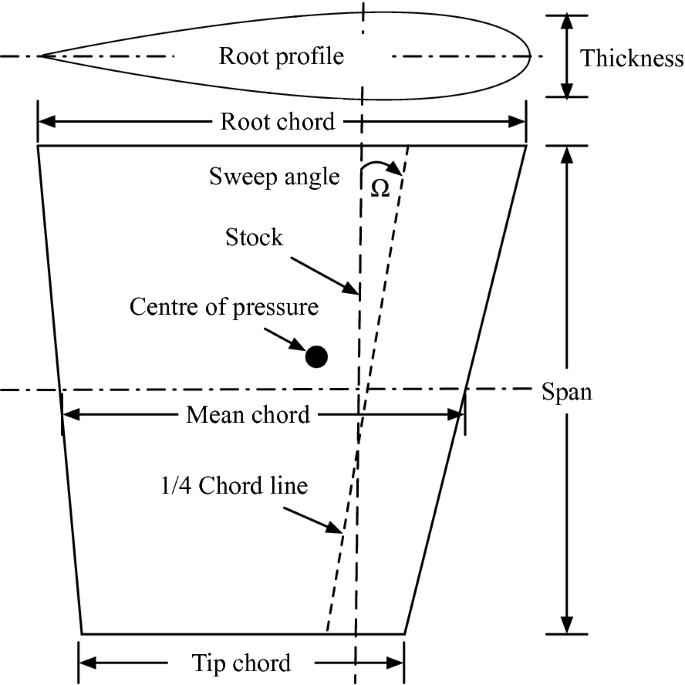

A typical rudder design for a displacement hull installs the stock of a spade rudder at about 25% of the chord distance from the leading to trailing edge (1/4 chord line). An area in front of the rudder stock moves the center of pressure forward, reducing steering ram torque requirements as forces act in unison on both the leading and trailing edges. A degree of imbalance reduces, and the situation is unaffected by the diameter of the stock itself but only by its axis.

(Image is a stock description of rudder terminology.)

There was a significant increase in force on the rudder's leading edge at surfing speeds. The effect was to move the center of pressure forward in front of the rudder stock. The steering rams could not overcome the increased torque requirements, and the steering became momentarily frozen.

A solution employed was to decrease the area on the leading edge by positioning the stock to around 18% (figures are approximate). Steve was referring to an FPB 70, but wait to quote me. The effect was tested by uncoupling the steering rams when tied to the dock and running the engines at full load. If the rudders tended to slam hard over, then the potential for imbalance existed. In my vernacular English, "this is a new one for me."

On Vanguard, the area in front of the rudder stock axis is 21.2% (18% <21.2%> 25%). It's too late to reposition anything, though we have the clearance to add material to the trailing edge, producing the same effect should sea trials indicate the need.

Hydraulic loads

The second issue was with the autopilot. I would start here by stating that FPB used the excellent Simrad autopilot, and the company was very responsive. Transient pressure spikes on the steering rams played havoc with the control logic within the autopilot unit. This novel condition triggered it to default to "safe" or "standby" mode, requiring a software modification. At the same time, the steering ram capacity was increased to provide a higher steering force, moving away from a potential hydraulic stall condition. An alternative would increase the torque arm length, though this was not geometrically possible on the vessel in question.

Vanguard has a commercial Wills Ridley steering system (see below), much in common with the Kobelt systems used by FPB. Naval Yachts has also maintained the tiller arm swing and resultant leverage. Our only significant differences are independent rams and pump per rudder and a deeper aerofoil section to the rudder blade as it wraps around the oversized rudder stock. It may make no difference, but we retain the potential to increase the ram capacity or tiller torque arm length within our design.

Roundup

There is no rule book for when a design pushes at the edges of accepted practice. Some are horrified by this; others run towards it. It is true, though, that few of us wish to end our days with the description of "He was normal."

Thank you, Steve Parsons, for your unique and helpful insight into the world where we will willingly play.

Chris Leigh-Jones

Useful links

Eyos Expeditions: https://www.eyos-expeditions.com

Circa Marine: https://circamarine.co.nz