Weely Update - Vanguard Launches!

- Chris Leigh-Jones

- Oct 5, 2023

- 3 min read

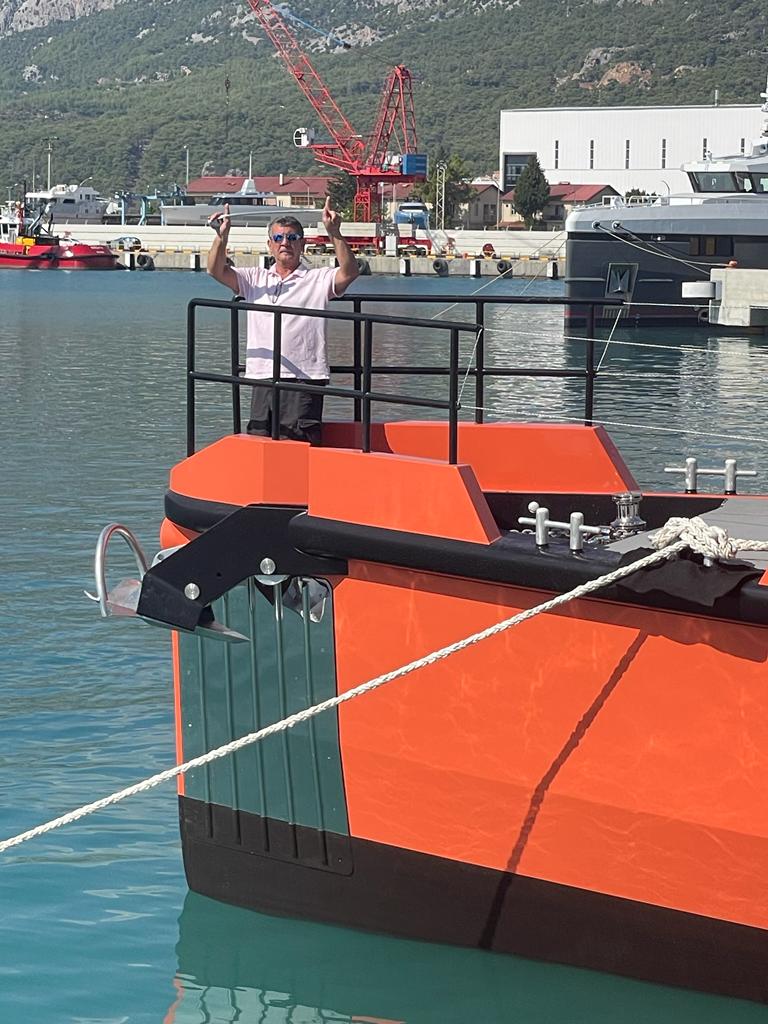

Like a family before Christmas, the last few weeks have been a flurry of activity as our Explorer Yacht, Vanguard, inched towards her completion.

There is nothing like a deadline; our yard set one, and that was the day it happened: Tuesday, 3rd October. After seemingly years of planning and building, we were about to get our first glimpse of our alternative future.

The launch process

Launching is a process like many others. The underbody of the hull is completed, antifouled, running gear attached, anodes in place, and chocks moved to paint the last few areas. Scaffolding was removed, and temporary handrails installed. Meanwhile, workers continued internally with the engine room, helm stations, and fitting Treadmaster high grip panels to the external decks. Chocks were then rationalized in number and repositioned so the transporter could manoeuver underneath to raise the hull from her slumber within the yard.

Out of the Yard and down to the travel lift next to Damen Shipyard. The hull of our explorer yacht was then transferred to this lift and slowly lowered into the waiting Medditteranian. Half in, and some 14 anxious yard employees were on board checking everywhere for potential leaks, which continued until she floated under her buoyancy.

Our Explorer Yacht floats with no leaks!

Vanguard had a distinct port list and quite a tendency to roll like a football as she wallowed in the dock before being towed to her temporary stern-to-mooring. This is a time when it's very easy to panic: what have we done? It's also a time for cooler heads or maybe more experienced ones. Vanguard is a light ship with no fluids on board, so the center of gravity is much higher than planned. A time when several launches have gone wrong, resulting in a capsize or partial one at best. So what happens now?

Initial results

The first thing was to assess what we have, the easiest point of reference being the top line of the antifouling.

Trim with 100mm below her marks on the stern and 500mm at the bow: 50 mm port list and a roll period of about 7.5 seconds. No one would go to sea in a hull behaving like this, but we have only started to trim her properly. Adding 3t of fresh water to the forward tanks, we have 150mm at the stern (which was gratifying), 300mm at the bow, and a 7-second roll period. Better, but we have a long way to go yet. The forward freshwater tanks will take in a total of 4.2t, and we can use one of the 1.5t aft tanks to correct the list. Globally, the hull will sink 12mm for each 1t added, and we

have some 150mm to her marks all around, assuming the stern continues to rise as the bow approaches the horizontal.

Video of my super tolerant wife, Sebrina, christening Vanguard in time honored fashion. She promosed not to miss with the bottle!

Independant advice from the experts

Given the resources that have gone into Vanguard, this early stage is nerve-wracking. Today, I feel slightly better, which I will take wholeheartedly. Dennis Harjarma from Artnautica is following as data arrives, and we have Eyos Expeditions helping with their expertise and experience of similar commissioning and voyaging with FPB hulls.

More in the next blog as we begin to understand what we have.

Chris Leigh-Jones

Years ago I watched a Royal Navy Type 23 frigate being launched stern first on the River Tyne in Newcastle upon Tyne, UK. They had two apprentices on the aft deck, underneath the flight deck. A truly mean trick, they got very wet on that day.

<3

Well done guys.

Congratulations. She is beautiful and strong. You will enjoy great adventures.

Wow! Brilliant. The tension!